What Is The Difference Between 3D Printer And 4D Printer?

Definition of 3D and 4D Printing

Printing technology has come a long way in the last few years, with 3D and 4D printing taking center stage. These printing techniques have revolutionized manufacturing and production, enabling businesses to create everything from simple prototypes to fully functional, complex structures. 3D printing is the most common among the two, but many people are still unfamiliar with 4D printing. In this article, we will define both 3D and 4D printing techniques and explore how they differ from each other.

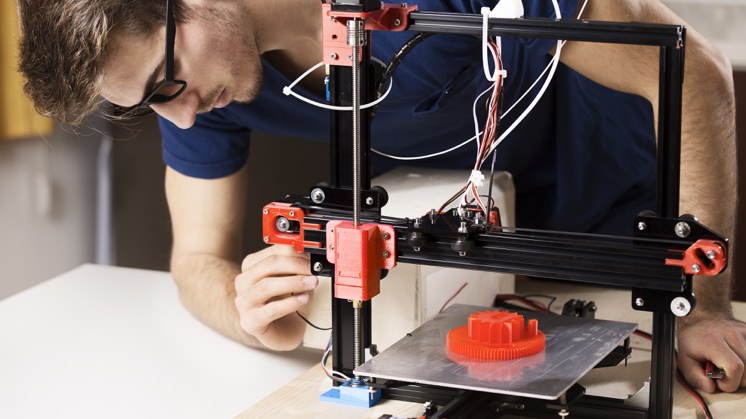

3D Printing:

3D printing is the process of creating 3-dimensional objects by laying down successive layers of material until the object is created. The process starts with a digital file created by a 3D modeling software or scanner. The file is then sent to the 3D printer, which reads the file and follows the instructions to create the 3-dimensional object, layer by layer.

The material used in 3D printing is typically thermoplastic or nylon. However, other materials such as metals, ceramics, and even food-grade materials can also be used. The printer uses a process called fused deposition modeling (FDM), where the material is melted and formed into the desired 3D shape.

3D printing has a variety of applications in manufacturing, healthcare, and engineering. It is used for creating prototypes, custom-made products, and even human organs.

4D Printing:

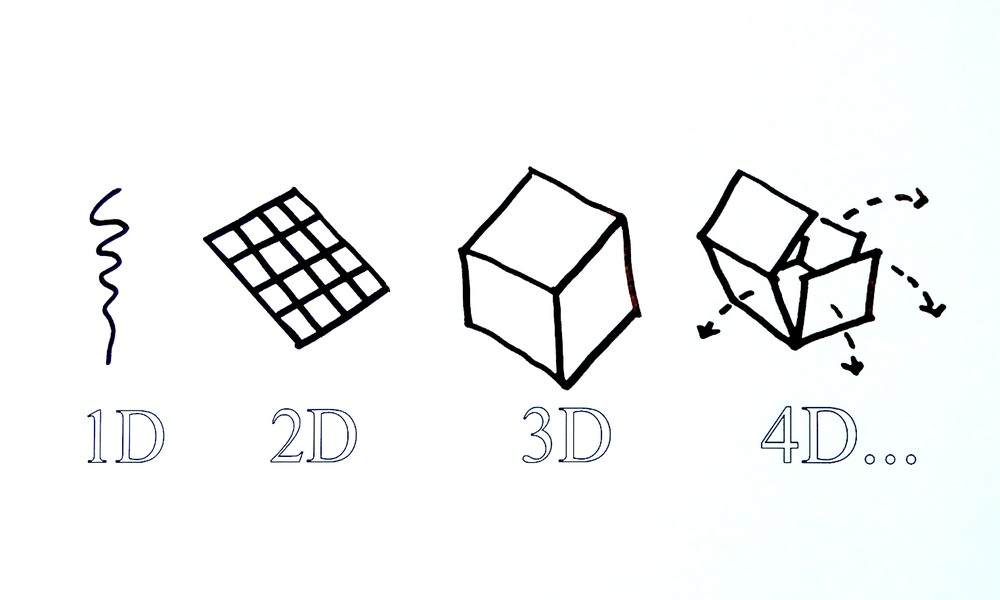

4D printing is an advancement of 3D printing technology. It is a new way of printing where the printed object can transform itself over time. This transformation is triggered by environmental factors such as heat, moisture, or light. By adding an extra dimension of time to the 3D printing process, 4D printing allows the printer to create objects that can adapt and transform.

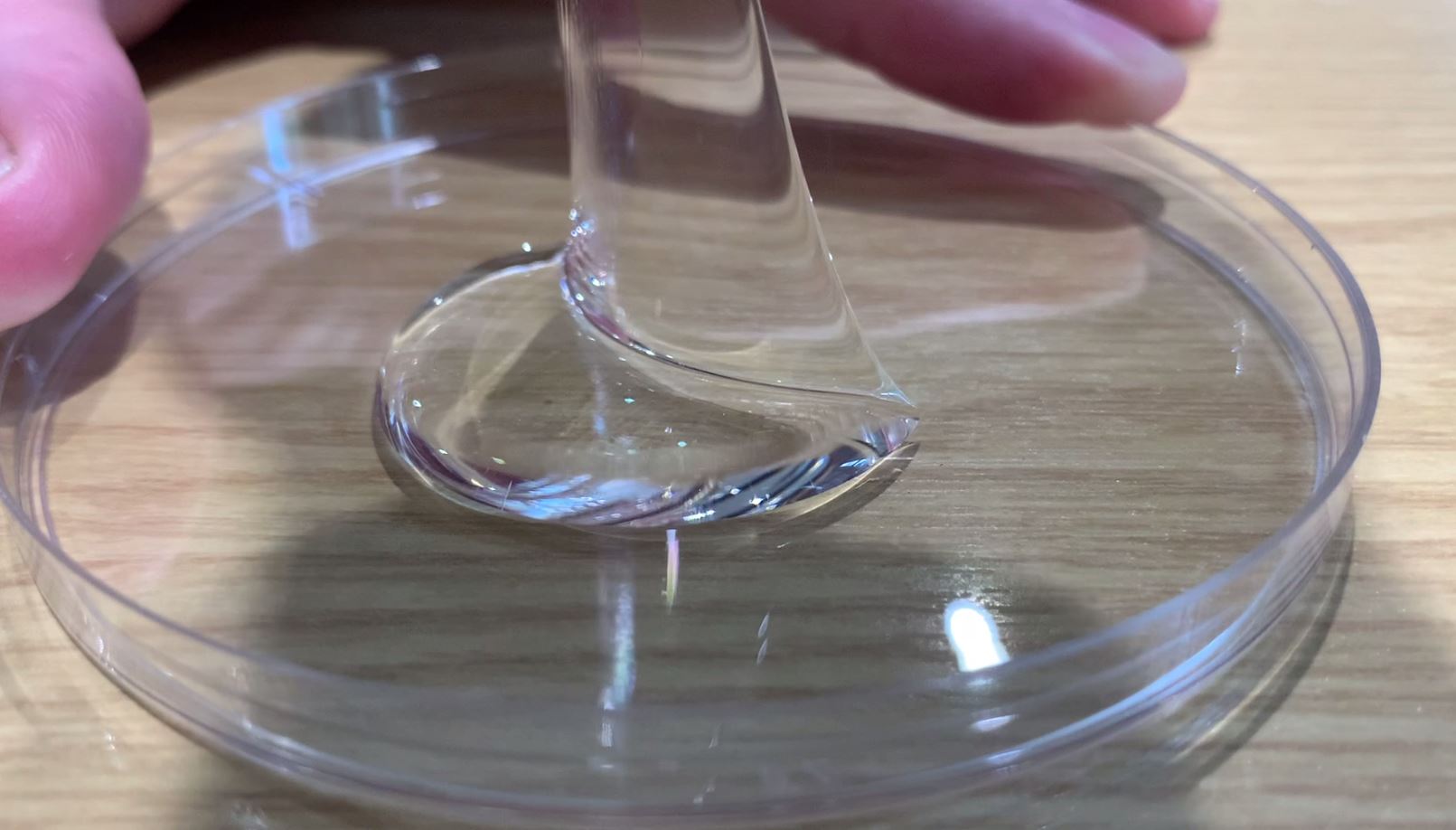

The material used for 4D printing is typically a special type of shape-memory polymer that can transform into different shapes under different conditions. The process of printing and configuring the 4D object is similar to 3D printing, but with an added step of heat treatment. This is done to allow the material to fix into its new shape.

4D printing has applications in healthcare, manufacturing, and even aerospace. It can be used to create self-assembling structures, adaptive structures, and smart materials.

Comparison of 3D and 4D Printer Technology:

While 3D and 4D printing share some similarities, there are a few significant differences between the two technologies. 3D printing is best for creating static, solid objects, while 4D printing is ideal for creating active, dynamic objects that can react to their environment.

Another fundamental difference is the materials used. 3D printing primarily uses thermoplastics and metal powders, while 4D printing uses specialized materials such as shape-memory polymers and smart hydrogels that can change shape based on various stimuli.

Moreover, 3D printing is easier to execute, more cost-effective, and is readily available in the market. On the other hand, 4D printing is still in a nascent stage, and the process is relatively expensive and time-consuming.

Finally, the end-use applications also differ significantly. 3D printing is mostly used in manufacturing, product development, and prototyping, while 4D printing finds a wide variety of applications in sectors ranging from biomedicine to aerospace.

Materials Used in 3D and 4D Printers:

The materials used in 3D and 4D printers differ significantly, with each technology requiring specialized materials to achieve the desired result.

In 3D printing, the most common materials are thermoplastics like ABS, PLA, and PVA. These materials can be melted and then solidified to form the desired shape. Other materials used in 3D printing include metals, ceramics, and food-grade plastics.

In contrast, 4D printing relies on specialized materials, such as shape-memory polymers and smart hydrogels. These materials can change shape when exposed to heat, moisture, light, or other types of energy. Therefore, engineers must select the right materials according to the specific application.

Another important factor in the material selection process is the stability of the final product. While 3D-printed objects are generally stable and can last a long time without degradation, 4D-printed structures that rely on changing their shape over time could be prone to instability if the chosen material degrades too quickly.

In addition, material costs and availability also play a role. Thermoplastics used in 3D printing are readily available in the market and relatively cost-effective, while shape-memory polymers and other advanced materials used in 4D printing can be expensive and challenging to source.

Future Applications of 3D Printing Technology:

3D printing technology is already being used in various industries such as aerospace, automotive, healthcare, and construction. However, with advancements in technology, the potential applications for 3D printing in the future are limitless.

One of the most significant future applications of 3D printing is in the field of medicine. 3D printing enables doctors to create accurate replicas of bones, organs, and other body parts, which can be used for research, teaching, or surgical planning. In the future, it may also be possible to use 3D printing to create complete organs for transplant patients, potentially eliminating the need for organ donors.

Another exciting application of 3D printing is in the field of food production. With 3D food printers, chefs can create unique shapes and textures that were never before possible, which could revolutionize the food industry. For example, 3D-printed chocolate sculptures and intricate sugar creations could become a staple at high-end restaurants.

Moreover, the construction industry could benefit significantly from 3D printing technology. Architects can use 3D printing to create detailed models and prototypes, enabling them to explore different designs and minimize waste. In the future, it may also be possible to use 3D printing to fabricate entire buildings, reducing costs and saving time.

Finally, the use of 3D printing has the potential to significantly reduce waste and energy consumption in manufacturing. With 3D printing, manufacturers can produce small batches of products quickly and efficiently, reducing the need for large-scale, mass production.

In conclusion, the future of 3D printing is bright, with endless possibilities for innovation. By exploring new applications and pushing the limits of technology, 3D printing continues to change the world around us.

No comments: